STT System - Solescan Rubra

Solescan Rubra is a three-dimensional foot scanner based on laser light which provides an accurate 3D model of a patient’s soles. The acquisition of precise and reliable digital data of the foot allows the doctor to detect underlying problems in foot function and gait that would otherwise be unseen. Additionally, the 3D foot model allows generating customized insoles quickly and with great precision.

Apart from soles (in loadbearing, semi-loadbearing, non-loadbearing positions), Solescan Rubra can actually scan phenolic foam casts and plaster models (or casts made from other materials).

The combination of Solescan Rubra with STT’s computer applications is a powerful tool for the production of insole orthesis which are tailor-made to individual patient needs.

Key features

- Very easy to set up and use

- Excellent sensitivity

- High resolution

- Color or monochrome, interline, progressive scan, with 640x480 resolution cameras

- Global electronic shutter allows capturing objects in high-speed motion

- 60 fps at full 640x480 or 100+ fps at 320x240 (binning mode)

Software

Acquisition software

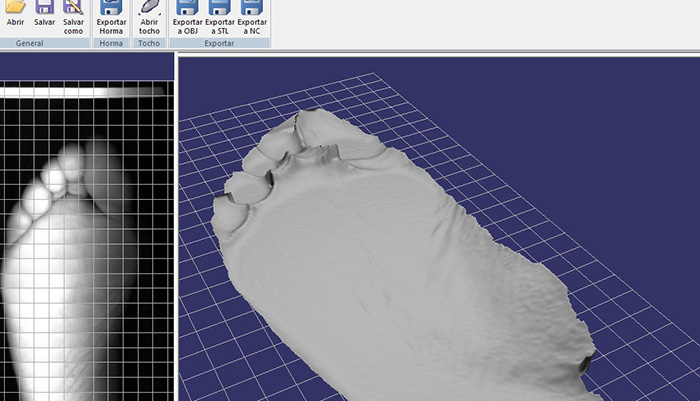

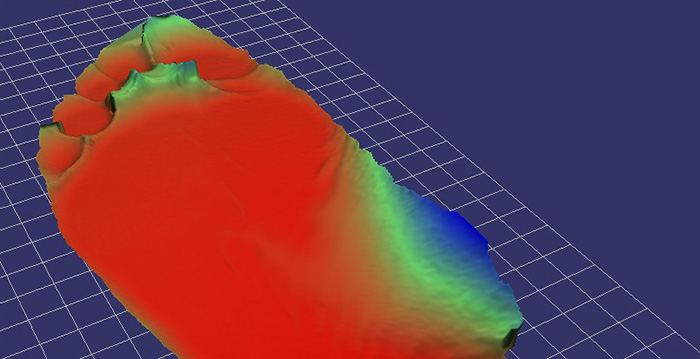

The complete Solescan Rubra package includes the latest version of STT scanning software, which is user-friendly and updated with the latest algorithms. The application allows the user to visualize the foot from different points of view; to carry out accurate measurements; to introduce additional notes; to define personalized insole orthesis; and to manage patient-related data in a comfortable way. 3D

Insole Studio

Insole Studio is the natural complement of Solescan Rubra. It allows the user to load digitalized surfaces generated with the scanner and to design customized soles in a straightforward way. Some of the key functions and tools of this software are described below.

|

|

Insole manufacturing

The last step to obtain made-to-measure insoles for patients is their manufacture. To do this, the Insole Studio numerical control (CNC) program is used to make insoles using different milling machines or robots. CNC file formats generated by Insole Studio:

-

G-Code

The most common and widely used programming language for numerical control machines like milling machines. -

NCP-ISEL

A specific numerical control machine programming system for ISEL cards. -

Robot KUKA

Insole Designer exports files in TAP format. These files contain the progamming instructions for KUKA robots for the machining of the customized insole, using three or six axes. -

CAM Applications

Insole Designer exports the insoles designed by the chiropodist in the following formats: STL, OBJ, DXF and VRML. These formats are accepted by CAM programs such as CUT3D, which generate the numerical control program for any kind of milling machine or robot. -

Materials

The customized insoles geenrated can be machined in almost all kinds of material, such as EVA (any density), polypropylene, etc. -

Thermoforming

Manufacturing thermoformed insoles requires the machining of the insole moulds. Insole Designer generates the files required for the machining of moulds for different materials, such as plaster, expanded polystyrene, etc.

Specifications

SCANNING PROPERTIES

| Scanning resolution | 0.04 mm / px |

| Precision (sub-pixelling techniques) | 0.1 mm |

CAMERAS

| Frame rate | 60-100 Hz |

| Image resolution | 640x480, 320x240 |

| Lens | C-Mount and CS-Mount option |

| Shutter | Global |

| Interface | USB 2.0 Hi Speed, B-type connector |

High sensitivity, auto white balance & adjustable exposure

LASER

| Laser class | Class II |

| Wavelength | 650 nm |

| Divergence | <2.0 mrd |

DIMENSIONS

| Width x Length x Height | 36.5 x 73.5 x 22 cm |

| Weight | 16 Kg |

Information

Please feel free to contact us at +852 2416 8321 or via email info@deltason.com for further information and quotation.